About us

Welcome to the best industrial center around the world.

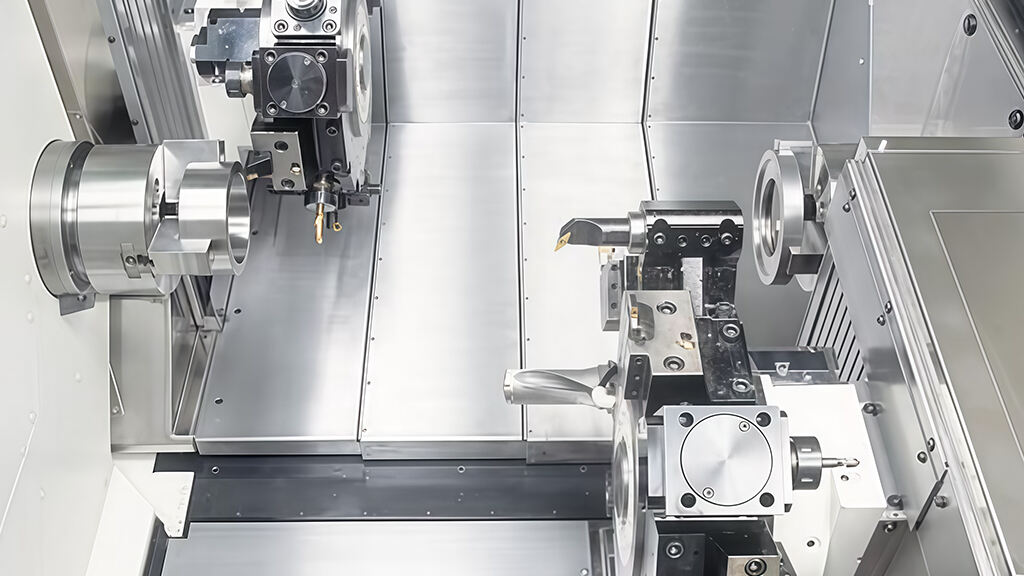

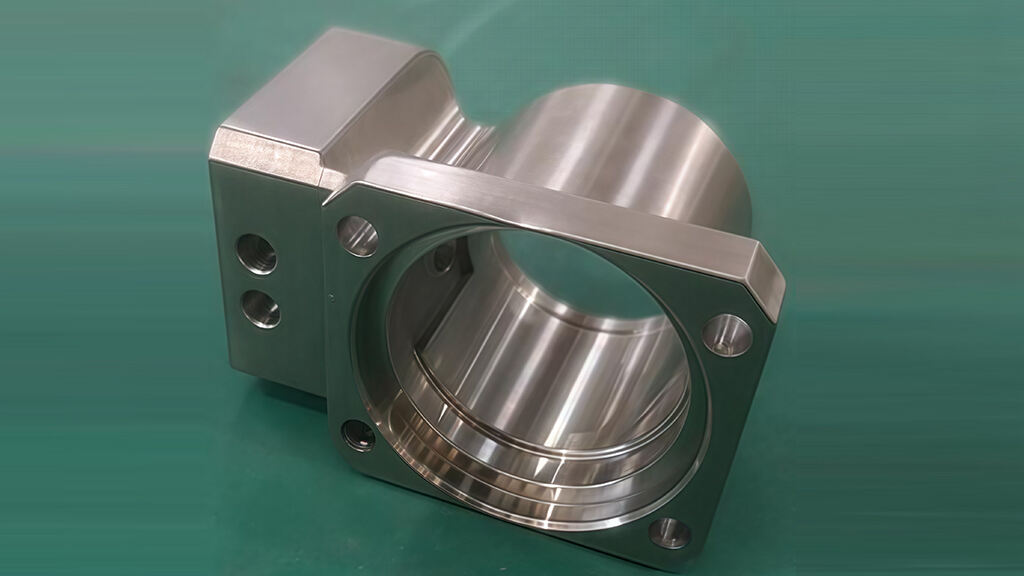

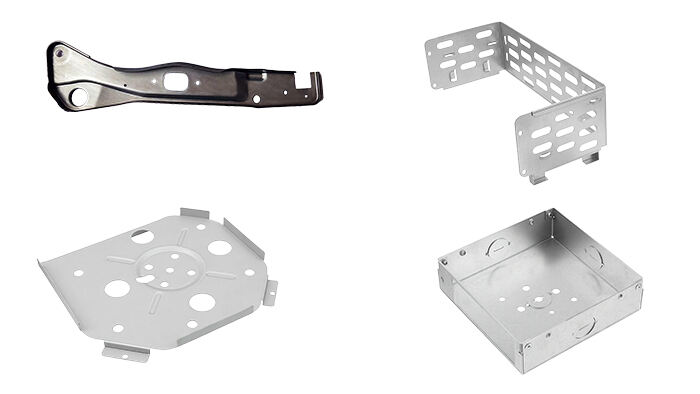

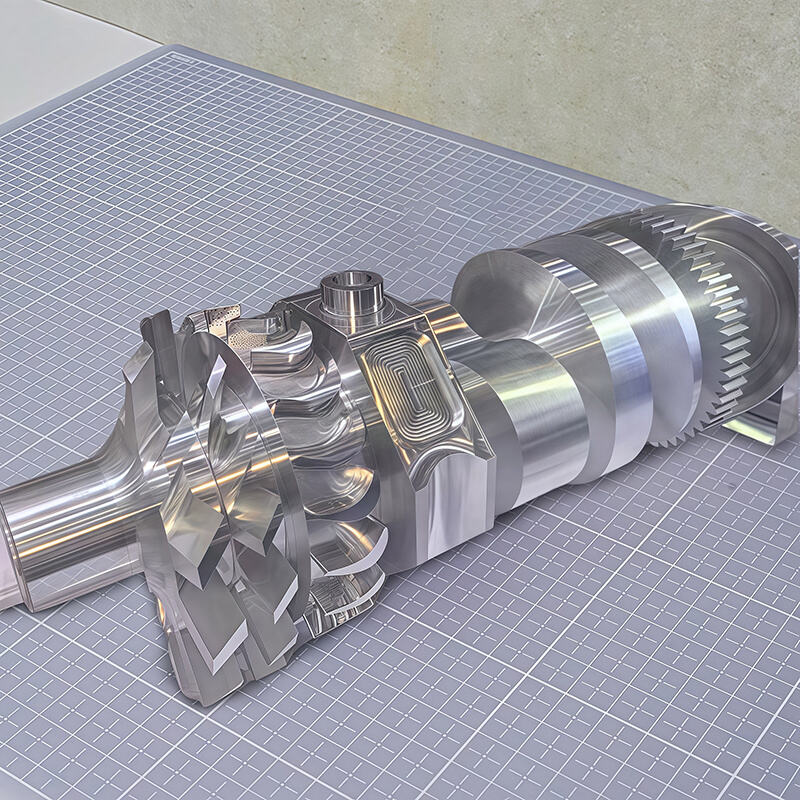

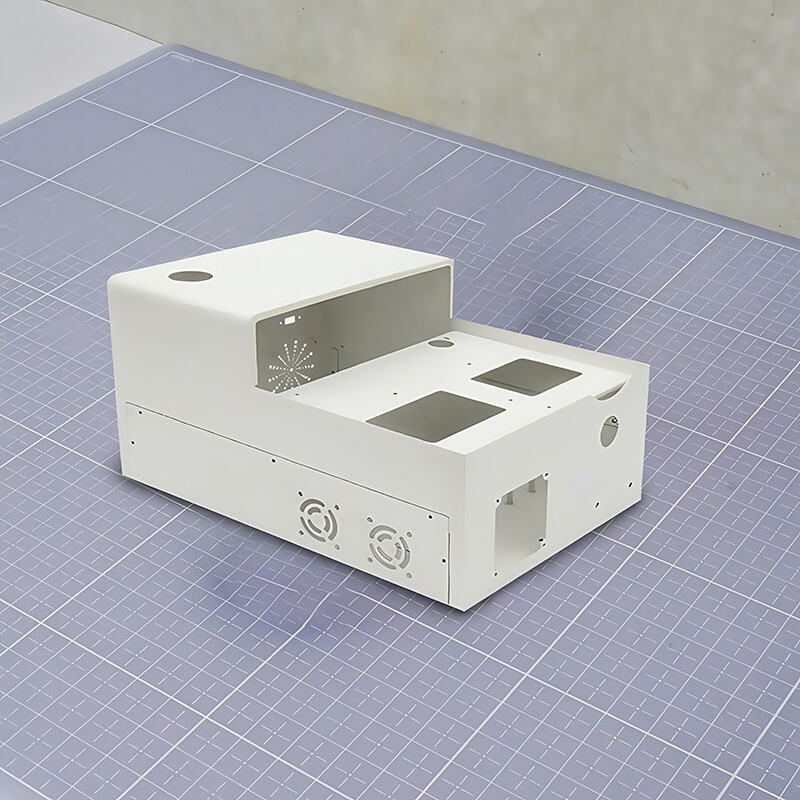

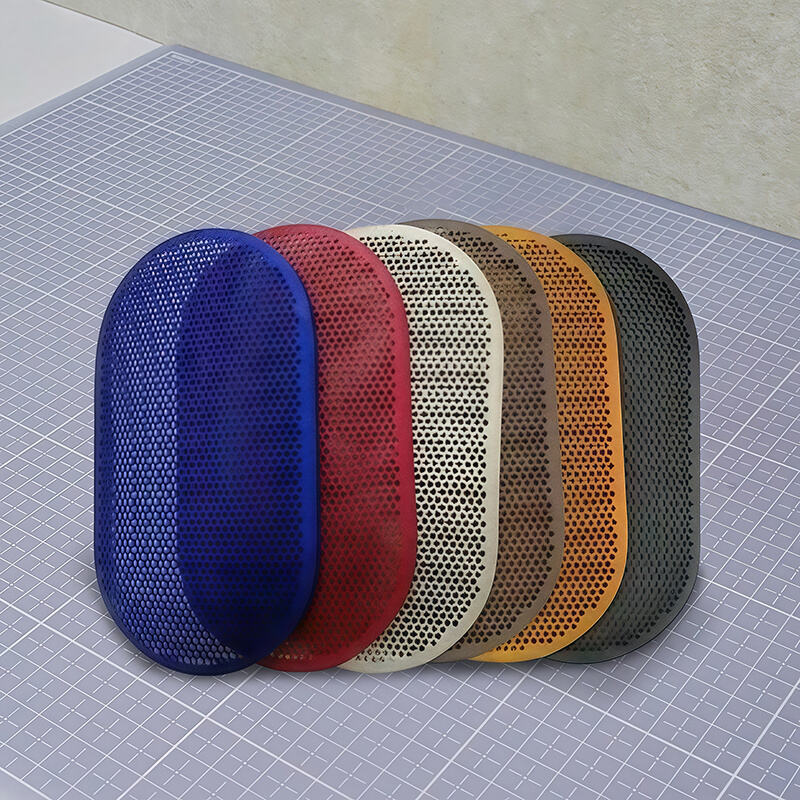

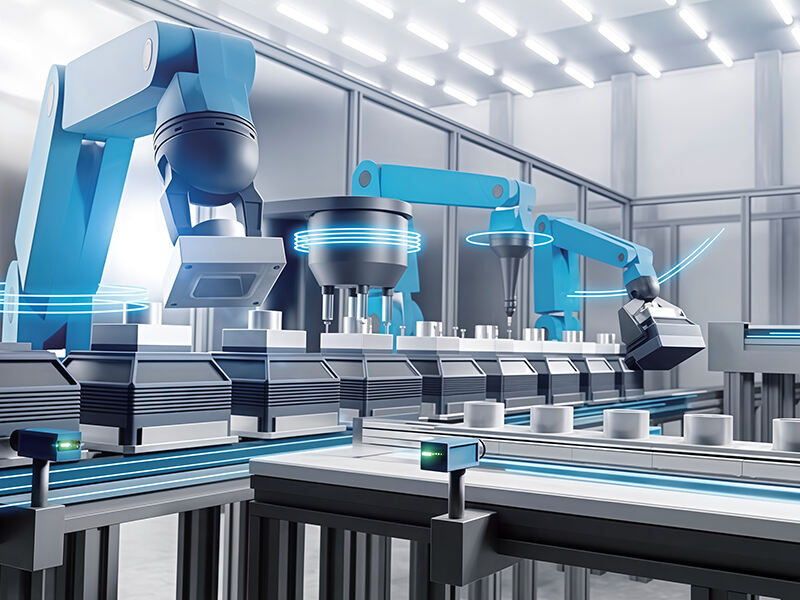

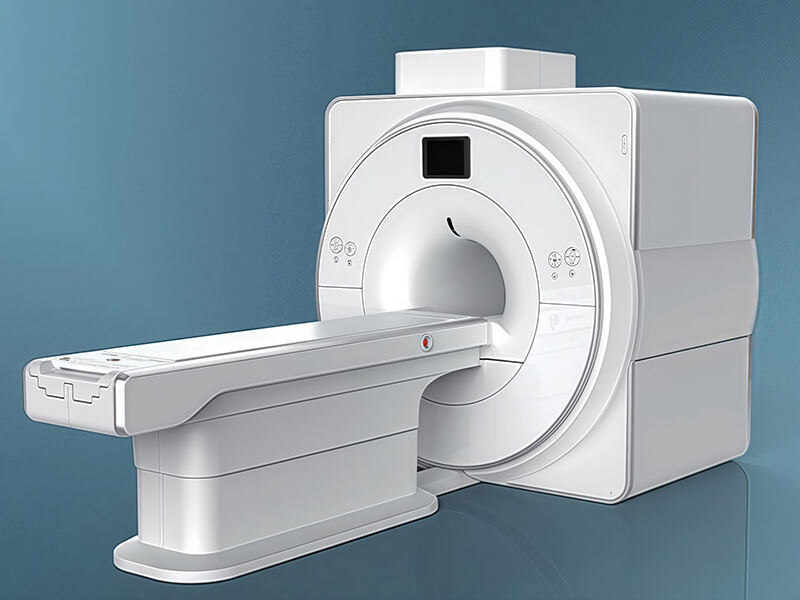

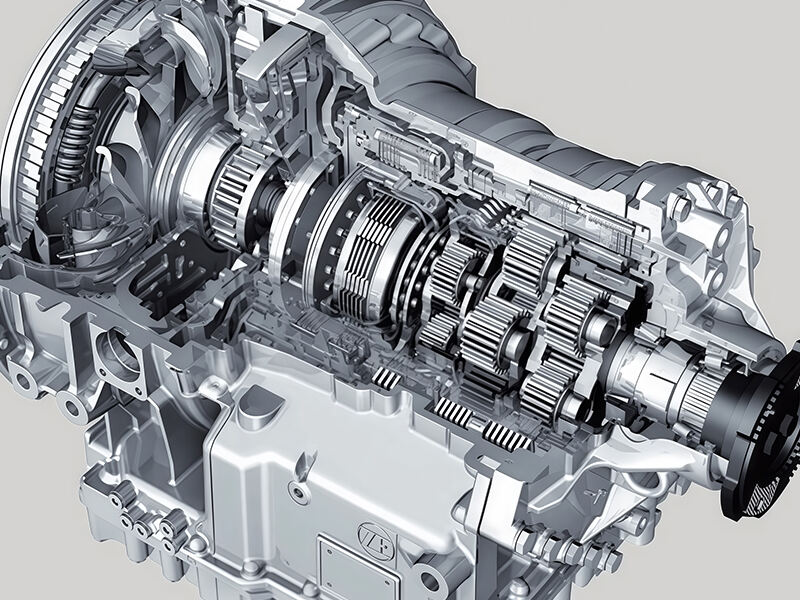

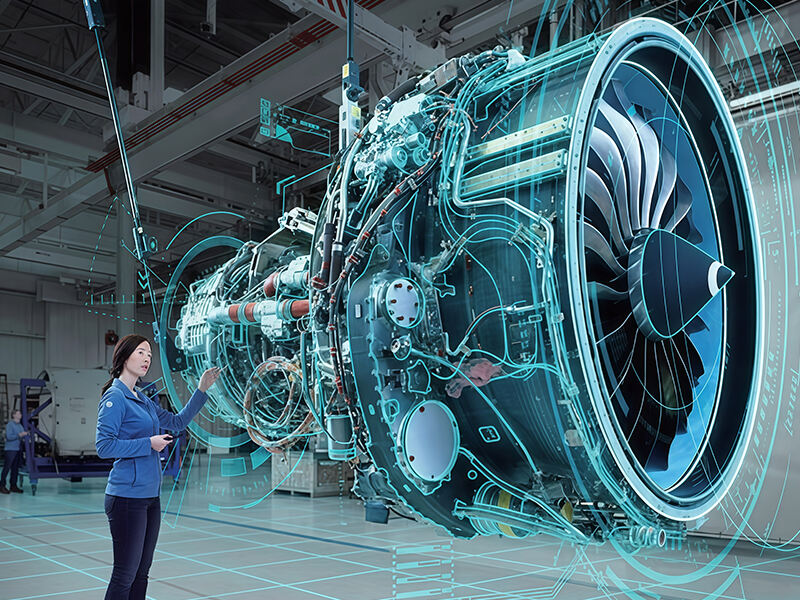

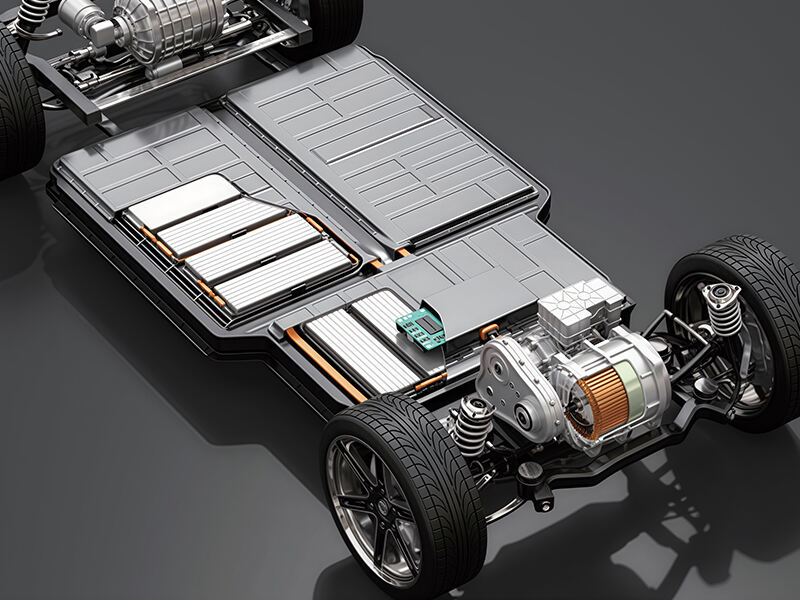

Haide Mingcheng Intelligence Science and Technology (Shenzhen) Co.,Ltd. was established in 2016, is a company focused on precision parts processing industry. Nearly 10 years of CNC industry technology experience has made rapid development, so far the company has high-end integrated processing equipment, CNC five-axis machine tools, wire cutting machine tools, EDM machine tools, grinding machines and lathes and milling machine equipment, from the real sense to achieve a one-stop service system. The company's service scope includes: robot industry mechanical structure parts, medical industry health testing equipment parts, automotive industry car body driving parts, automation equipment components, new energy industry battery components, aerospace industry auxiliary transmission parts.

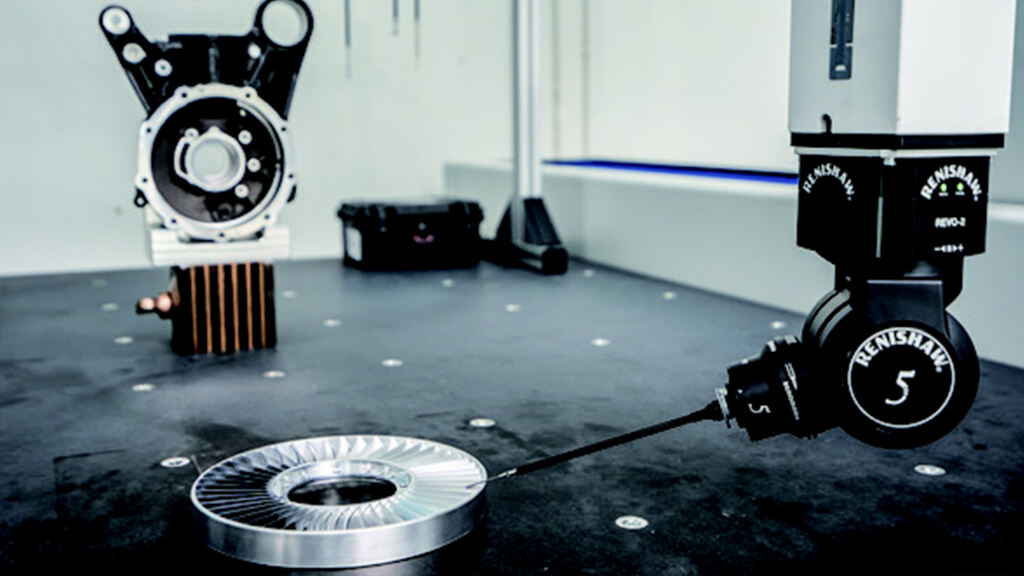

High quality

Our testing skills are of rigid technology Diving quality testing into the whole production system

Fast delivery

Making a Certain Quote within 4 Hours Put Order into Production Quickly